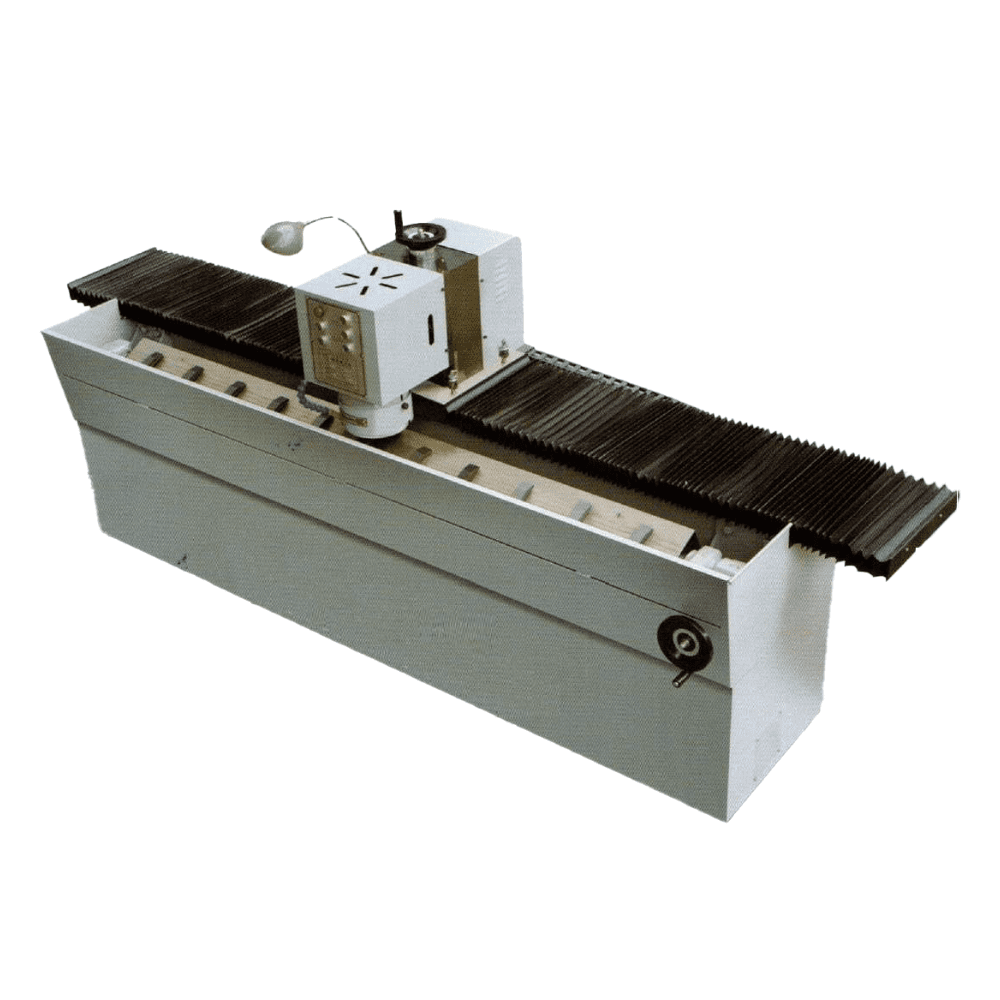

Mesin ini merupakan generasi kedua dari end mill sharpener yang dikembangkan oleh perusahaan kami. Menggunakan konstruksi integral dengan desain elegan, struktur yang ilmiah, dan kualitas pengasahan yang presisi. Sangat dibutuhkan sebagai mesin asah pisau (blade sharpening equipment) untuk industri percetakan, kertas, woodworking, plastik & kulit sintetis, tisu, dan sektor manufaktur lainnya.

Keunggulan Teknis:

-

High-Frequency Quenching

Proses quenching frekuensi tinggi memberikan kekuatan tinggi, ketahanan aus (wear resistance), serta stabilitas yang meningkatkan usia pakai mesin. -

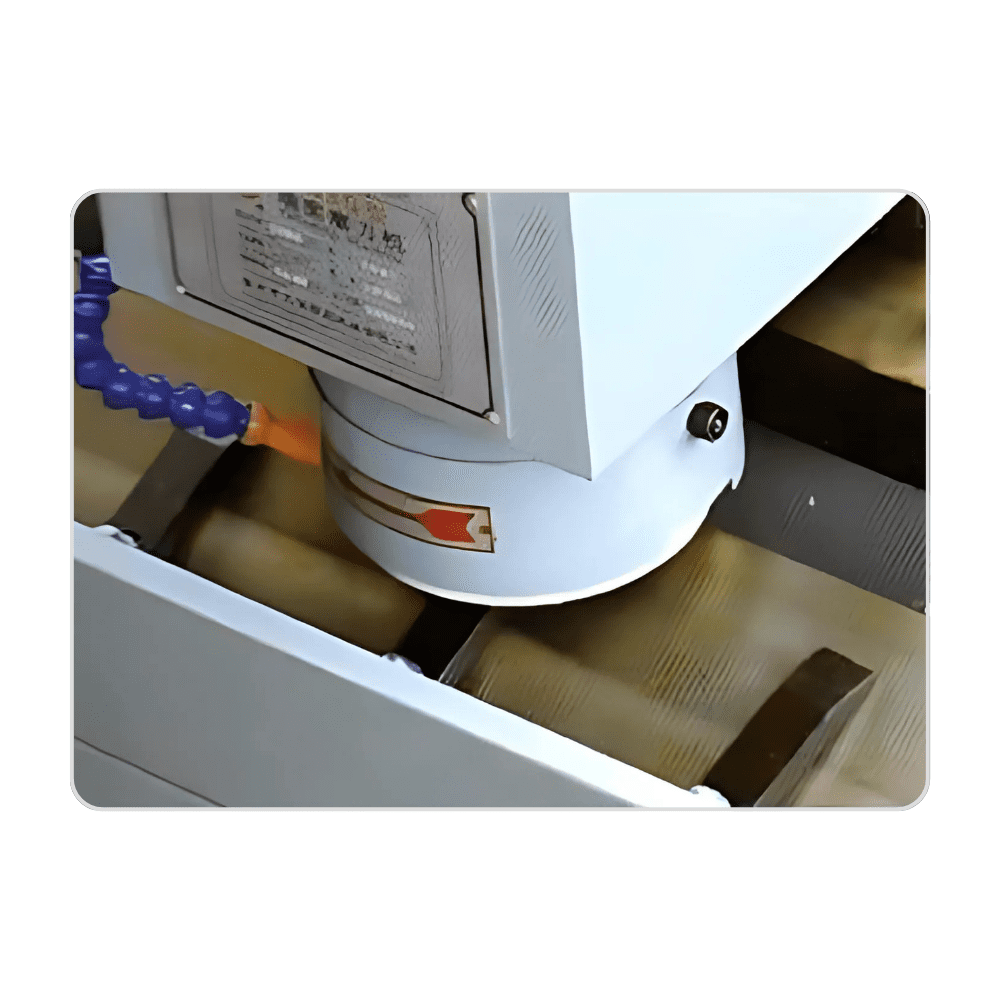

Self-Aligning System

Sistem self-aligning menghasilkan gerakan yang halus, stabil, dan presisi tinggi saat pengasahan pisau. -

Multi-directional Durability

Mesin tahan beban dari berbagai arah: atas, bawah, dan samping, sehingga lebih kokoh untuk penggunaan industri.

Konfigurasi Dust Cover (Penutup Debu)

-

Dibuat dari non-woven fabric dengan teknologi high-frequency hot sealing dan compression molding.

-

Efektif untuk perlindungan terhadap debu, air, oli, serta membantu peredaman suara dan meningkatkan lingkungan kerja.

-

Memiliki ketahanan terhadap asam dan basa, serta anti-korosi untuk memperpanjang umur pakai.

-

Tidak mudah deformasi saat terkena benturan atau getaran, serta memiliki tingkat elastisitas dan kompresi yang tinggi.

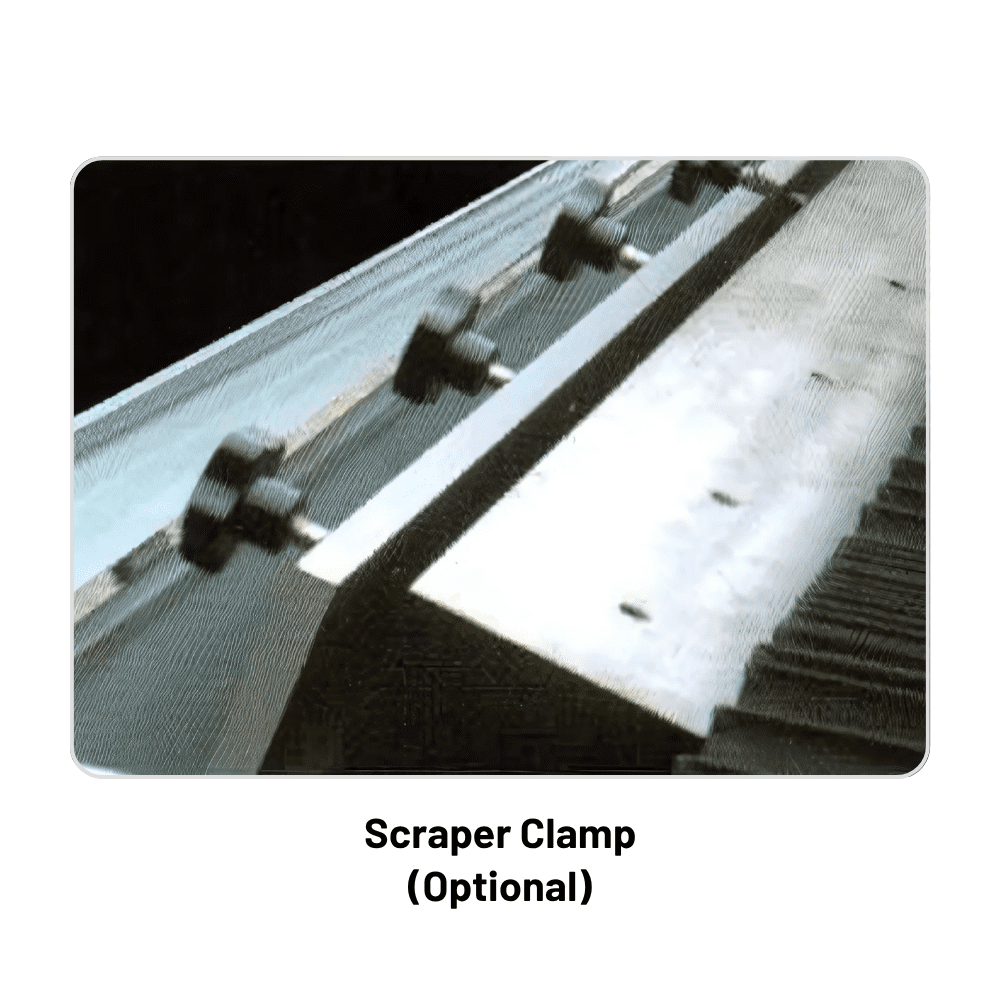

DMSQ-1600ZII Knife Grinding Machine With Accessories

| Models | DMSQ-1600ZII |

| Grinding wheel dimension | Φ200 × Φ100 × 100 mm |

| Maximal knife grinder width | 22° / 180 mm |

| Height (grinding wheel and work bench) | 80–120 mm |

| Work bench rotation angle | 0 ~ ±90° |

| Grinding speed | 1420 r/min |

| Grinding head movement speed | 6 m/min |

| Driving motor power | 0.55 kw |

| Grinding head motor power | 1.5 kw |

| Water pump motor power | 0.125 kw |

| Effective length of sharpener | 1600–8000 mm |

| Machine weight | 1550 kg |